Related stories:

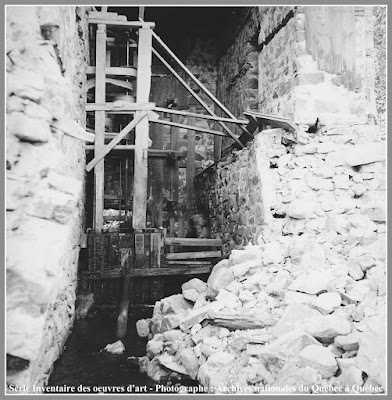

First built in 1825 on the Rémy River in Baie-Saint-Paul against the densely forested backdrop of the Charlevoix mountains in Central Quebec, the mill produced flour from 1826-1827 to 1950. When the undershot wheel fell apart, it was replaced by a turbine and the miller, Félix Fortin, switched to producing animal feed. In the late 80's, Fortin retired and the mill stood abandoned until bought by Heritage Charlevoix in 1992 (see The Gift of Bread ). Restoration work started in 1997. The mill started producing flour again in 2007.

A page from the booklet The Moulin de la Rémy

See A Quebec Story...

Meunier, tu dors, ton moulin, ton moulin va trop vite !

Meunier, tu dors, ton moulin, ton moulin va trop fort !

(Miller, you are sleeping, your mill is spinning too fast!

Miller, you are sleeping, your mill is spinning too hard!)

This age-old French children's song sounds a warning that today's miller must heed like generations of millers before him or her. A mill that spins too fast increases the risk of an explosion because the silex stones can produce sparks that might set fire to the flour and dust particles present in the air and a mill that spins too hard might crush the grain and give the flour a stony taste. Patrick, the head miller at the mill on the Rémy, describes his work as organoleptic: he must constantly listen to the stones, touch the flour and smell the air to make sure the mill is spinning correctly. Any unusual vibration or creaking noise and he springs to action. Ernest revealing the revolving sifter inside the bolter

Patrick showed me around the mill which he appears to know as intimately as the palm of his hand. He is very proud of the white-oak wheel. Larger than most wheels found elsewhere in Quebec, it measures 24 feet (7.3 m) in diameter and is 4 feet (1.22 m) wide and is mounted on ball bearings. An exact replica of the original wheel, it was built to specifications in Bernier's workshop.

The mill has three pairs of grindstones, each one dedicated to a specific grain. Right now it only produces wheat flour but buckwheat is next in line and will be milled with its own pair of stones. Of each pair, only the top one turns: it is called the runner. The bottom one is stationary and is called the bedstone. The stones come from La Ferté-sous-Jouarre in an area of France where the flint is just of the right quality. Were it harder, the stones would get smooth fast and the grain would roll around instead of being ground. Were it softer, they would wear out and crumble and stone particles would be mixed with the flour. Quebec flint is not porous enough, so that it heats up quickly and isn't suitable for milling.

I won't even try to describe the axles, gears, wheels, pulleys and belts which activate the various mechanisms. Despite Patrick's excellent and detailed explanations, I cannot say I remember all of it, so I would probably make tons of mistakes. Also, if you are like me, you may be mostly interested in the final product, the flour! But in case you really want to know, a very good description of watermills is to be found in Wikipedia.

The Rémy River

The Rémy River

In the old days, the grain was stored in the attic from where gravity drove it into a large funnel above the millstones. Today it still comes to the millstones from the attic through the funnel but it is stored in a modern granary at the back of the mill. Once ground, the flour goes to the bolter inside which a sifter separates the various grades: white flour, germ and bran. Like the wheel, the bolter is an exact replica of the original one which had deteriorated beyond recovery.

The whole-wheat flour doesn't go into the bolter since it doesn't need to be sifted.

I was given some flour from the mill, both white and whole-wheat, to test at home. The all-purpose flour was fine but I was particularly impressed by the whole-wheat flour which I found surprisingly light and mild-tasting. Both flours seemed to absorb water less readily than their US commercial counterparts I am used to working with. I had thought the opposite would be true since they were milled from local wheat and due to the harsher climate, Canadian wheat is normally richer in protein than US wheat. Usually protein-rich flours absorb more water. It may just have been that batch of wheat. In any case, it confirmed for me what bakers always say: when making bread, go easy with the water until you know your flour!

For all practical info regarding the mill and/or the bakery, please refer to the Moulin de la Rémy's website.